Aluminum Casting: Techniques, Advantages, and Industry Applications

Aluminum casting is a critical process in modern manufacturing, employing multiple methods such as die casting and sand casting. Each approach delivers specific advantages, supporting the creation of detailed components with precision. The material's lightweight and corrosion-resistant nature boosts its value across numerous industries. Yet, the full scope of its implementations and the newest innovations in casting techniques remain to be investigated, demonstrating a constantly evolving field in aluminum manufacturing.

Various Aluminum Casting Methods: Sand to Die Casting

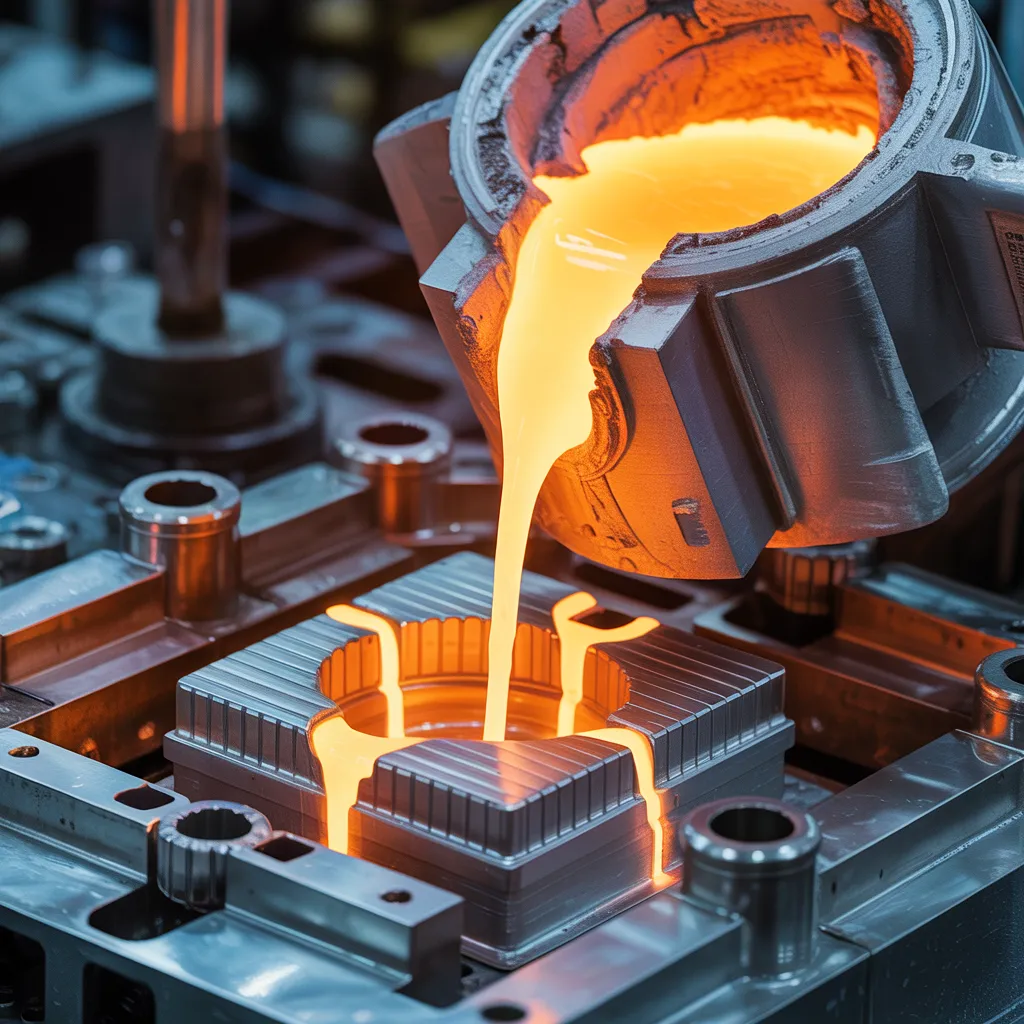

The aluminum casting process involves multiple techniques, each designed for different applications and requirements. One popular method is sand casting, where a mold is formed using sand and resin, permitting intricate designs and large parts. Another technique, shell molding, utilizes a thin shell of sand that delivers a smoother finish and improved dimensional accuracy. Die casting, a process that uses high pressure to inject molten aluminum into a metal mold, is well-suited for high-volume production and offers excellent surface finish and detail. Moreover, investment casting, which employs a wax pattern coated with ceramic, permits the production of complex shapes with tight tolerances. Last but not least, gravity casting uses gravity to fill the mold, appropriate for larger components but less precise than die casting. Each process has specific advantages, making them appropriate for varying industrial needs and product specifications.

Essential Advantages of Aluminum Casting for Manufacturing Processes

Although multiple manufacturing processes exist, aluminum casting excels owing to its numerous advantages. One notable benefit is its capacity to generate complex shapes with high dimensional accuracy, decreasing the need for extensive machining. This efficiency leads to reduced production time and lower costs. Moreover, aluminum's lightweight nature presents an advantage in industries looking to increase fuel efficiency and reduce overall mass in products.

Aluminum's outstanding resistance to corrosion increases the durability of cast components, making them appropriate for multiple environments. In addition, aluminum casting provides a variety of surface finishes, presenting aesthetic options for manufacturers. The material's recyclability also promotes sustainability, aligning with full details modern manufacturing demands for eco-friendly practices. In conclusion, the wide availability of aluminum alloys guarantees that manufacturers can identify materials tailored to specific performance requirements, increasing the versatility of aluminum casting in fulfilling diverse manufacturing demands.

Industrial Uses of Aluminum Casting: Key Applications

When considering industrial applications, aluminum casting becomes indispensable across numerous sectors because of its unique properties. In the automotive industry, aluminum castings are commonly used for engine blocks, transmission cases, and various structural components, enabling vehicle lightweighting and fuel efficiency. The aerospace sector also benefits from aluminum casting, where components like aircraft frames and engine parts necessitate materials that combine strength with reduced weight.

Furthermore, the electronics industry employs aluminum castings for protective housings and thermal management systems, which efficiently disperse heat while providing durability. In the construction sector, aluminum castings are used for architectural elements and window frames, presenting both aesthetic appeal and resilience. Beyond that, the manufacturing of consumer goods, such as cookware and appliances, regularly utilizes aluminum casting, highlighting its versatility. In summary, aluminum casting plays a crucial role in boosting performance and innovation across numerous industries.

New Breakthroughs in Aluminum Casting Approaches

Modern innovations in aluminum casting techniques have significantly elevated the productivity and quality of production across numerous industries. Particularly, innovations such as 3D printing and computer-aided design (CAD) have empowered manufacturers to create sophisticated geometries that were previously problematic to achieve. These technologies support rapid prototyping and decrease lead times, enabling more flexible production processes.

Furthermore, developments in alloy composition have improved the mechanical properties of cast aluminum, resulting in lighter and stronger components. Processes like high-pressure die casting and vacuum casting have also developed, reducing porosity and enhancing surface finish.

The integration of smart manufacturing systems, including IoT and automation, has improved production schedules and decreased waste. Improved thermal management techniques have led to better temperature control during casting, further increasing dimensional accuracy. Collectively, these advances not only boost product quality but also support more sustainable manufacturing practices in the aluminum casting industry.

Aluminum Casting's Environmental Impact: Recycling and Sustainability

As the aluminum casting industry evolves, its environmental impact grows more substantial, encouraging a greater emphasis on sustainability and recycling practices. The production of aluminum is resource-demanding, often leading to substantial greenhouse gas emissions. To counter these effects, many companies are implementing more sustainable methods, such as employing renewable energy sources and improving energy efficiency in their operations.

The recycling of aluminum is notably advantageous, as it demands only 5% of the energy required for primary production. This not only minimizes emissions but also saves natural resources. The implementation of closed-loop recycling systems further reduces waste and facilitates the reuse of materials.

Moreover, progress in casting technology are paving the way for the introduction of eco-friendly alloys that lower environmental consequences. As stakeholders increasingly prioritize eco-conscious practices, the aluminum casting industry is positioned to play a significant role in championing environmental stewardship while fulfilling the demands of modern manufacturing.

Frequently Asked Questions

What Alloy Varieties Are Used in Aluminum Casting?

Various aluminum alloys are utilized in casting, including 2xx.x, 3xx.x, 4xx.x, 5xx.x, and 7xx.x series. Each alloy presents distinctive properties, making them appropriate for multiple applications and optimizing performance in distinct environments.

How Does Temperature Impact the Aluminum Casting Process?

Heat levels substantially impact aluminum casting processes by altering fluidity, solidification rates, and mechanical properties. Higher temperatures enhance fluidity for elaborate structures, while decreased heat levels may produce faster cooling, affecting the final product's strength and integrity.

Can You Perform Aluminum Casting at Home?

Performing aluminum casting at home requires appropriate equipment and safety protocols. Practitioners commonly employ small-scale furnaces and molds, yet must comply with safety procedures to control elevated temperatures and melted metal management properly.

Which Safety Measures Are Required During Aluminum Casting?

Proper safety procedures while performing aluminum casting include donning protective apparel, such as gloves and goggles, ensuring adequate ventilation, using heat-resistant surfaces, and keeping flammable materials away from the workspace to stop accidents and injuries.

How Long Does Aluminum Casting Typically Require?

The aluminum casting process typically takes between several hours and a few days, depending on factors such as the complexity of the mold, the casting method employed, and the required cooling period for the casted aluminum.