Exploring Aluminum Metal Casting: Superior Long-Lasting Parts for Industry and Manufacturing

Aluminum metal casting serves a crucial function in contemporary manufacturing. It offers manufacturers the ability to produce durable, lightweight components that can enhance overall product performance. Various techniques, from sand to die casting, allow for design flexibility and precision. Understanding the nuances of alloy selection and production processes can greatly impact the results. As industries develop, so do the obstacles and innovations in aluminum casting. What approaches can improve efficiency and quality in this critical process?

How Your Manufacturing Process Gains from Aluminum Casting

Aluminum casting offers numerous advantages that can considerably strengthen the manufacturing process. Its reduced weight properties allows for the production of parts that are less difficult to process and transfer, thereby reducing operational costs. Furthermore, aluminum ensures exceptional corrosion resistance, increasing the lifespan of components in various environments. The superior thermal and electrical conductivity of aluminum makes it perfect for applications in automotive and electronics industries, where thermal management is critical.

In addition, aluminum can be effortlessly molded into complex shapes, allowing for intricate designs that meet specific engineering needs. The process also allows for reduced tooling costs and shorter lead times, which is essential in today's fast-paced market. In addition, the recyclability of aluminum promotes sustainability efforts, making it an eco-friendly choice. On the whole, these benefits position aluminum casting as a advantageous technique that can substantially enhance efficiency and product quality in manufacturing.

Standard Processes Applied in Aluminum Metal Casting

Metal casting with aluminum employs different methods that meet varied manufacturing demands. Two common methods are die casting and sand casting, both offering distinct benefits and applications. Grasping these techniques is crucial for enhancing production efficiency and achieving intended finished products.

Sand Casting Methods

A variety of sand casting techniques are commonly used in the aluminum metal casting process, each offering unique strengths depending on the project's demands. The most popular technique is green sand casting, which incorporates a mixture of sand, clay, and water. This method ensures excellent moldability and is cost-effective for small to medium production runs. Another technique, called resin sand casting, includes resin into the sand mixture, increasing the mold's strength and surface finish. In addition, shell molding involves creating a thin shell of sand and resin around a pattern, providing better dimensional accuracy and smoother surfaces. Each technique is determined based on factors such as production volume, complexity of the part, and desired finish quality.

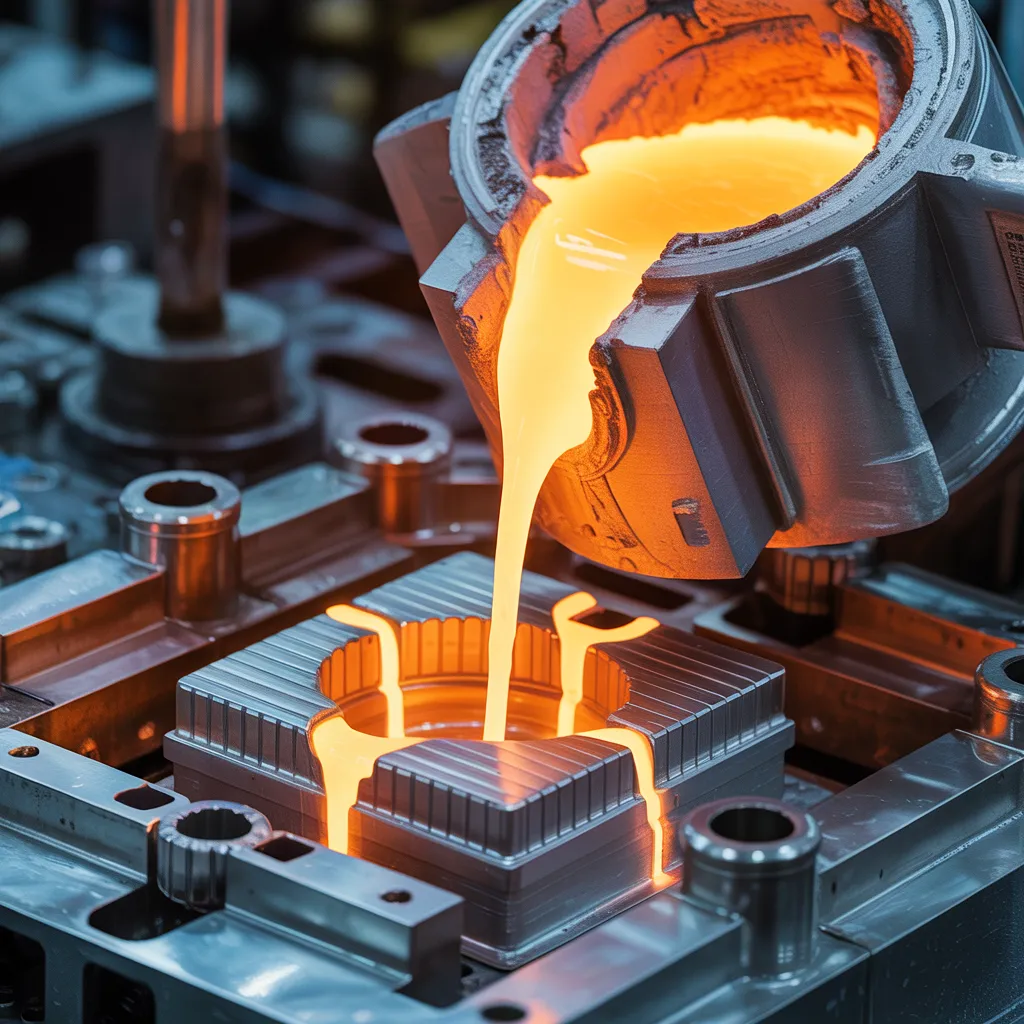

Die Casting Processes

Various die casting methods are employed in the aluminum metal casting industry, each customized to meet specific production requirements and design complexities. The two primary methods are hot chamber and cold chamber die discussion casting. Hot chamber die casting is suitable for low-melting-point metals and enables for rapid production cycles, making it effective for high-volume manufacturing. Conversely, cold chamber die casting is perfect for aluminum and other high-melting-point alloys; it requires injecting molten metal into cold molds, ensuring greater control over the metal's properties. Moreover, pressure die casting ensures uniformity and precision in the final product, while vacuum die casting minimizes gas entrapment, improving part integrity. Each approach presents distinct advantages, making them important for diverse industrial applications.

Picking the Correct Aluminum Alloys for Casting

Picking the appropriate aluminum alloy for casting is critical, as alloy composition directly impacts the final product's properties. Compatibility considerations with the selected casting process also plays a major role in achieving desired outcomes. Furthermore, understanding the mechanical characteristics of diverse alloys can guide decision-making to meet specific application requirements.

The Importance of Alloy Composition

Picking the appropriate aluminum alloy is essential for reaching superior performance in casting applications. The composition of aluminum alloys greatly influences their mechanical properties, corrosion resistance, and thermal conductivity. Common alloying elements, such as silicon, copper, and magnesium, are added to enhance specific characteristics like strength and ductility. For example, silicon increases fluidity, making it ideal for intricate castings, while magnesium increases strength, making alloys ideal for structural components. Understanding the composition enables manufacturers to select alloys that fulfill the specific needs of the application, whether it be for automotive parts or industrial machinery. In the end, the right alloy composition not only provides durability but also optimizes production efficiency and cost-effectiveness in the casting process.

Compatibility with Casting Processes

Grasping alloy composition is only one facet of enhancing aluminum casting; the compatibility of the preferred alloy with specific casting processes is equally important. Different casting methods, such as sand casting, die casting, and permanent mold casting, require distinct alloy properties to achieve superior results. For instance, die casting often works best with alloys with lower melting points and exceptional fluidity, while sand casting may use alloys that exhibit strong strength and ductility. Moreover, the thermal and mechanical attributes of the alloy must correspond to the requirements of the preferred process to reduce defects and guarantee dimensional accuracy. In the end, selecting the right aluminum alloy based on casting process compatibility is vital for producing superior-quality, durable components customized for industry needs.

Mechanical Properties Overview

The mechanical properties of aluminum alloys play an essential role in determining their suitability for various casting applications. These properties, including tensile strength, ductility, hardness, and fatigue resistance, are critical factors in selecting the right alloy for specific industrial needs. Alloys such as 356 and 319 are favored for their excellent castability and mechanical performance, making them ideal for automotive and aerospace components. In addition, the alloy preference can determine corrosion resistance and thermal conductivity, characteristics that are basic to many applications. Recognizing the relationship between strength and weight is likewise crucial, as diverse alloys deliver distinct performance degrees. Eventually, determining the right aluminum alloy secures that cast pieces comply with the exacting needs of their intended function.

Tips for Profitable Aluminum Casting Projects

Well-executed aluminum casting projects require meticulous planning and close attention to specifics. First, it is vital to select the suitable aluminum alloy according to the desired mechanical properties and application specifications. Appropriate mold design is imperative; molds should be constructed to enable smooth metal flow and eliminate defects. Additionally, maintaining uniform temperatures throughout the casting process is vital for achieving uniform results.

Acquiring high-quality equipment, including furnaces and pouring systems, can greatly influence the outcome. It is also recommended to conduct thorough pre-casting inspections to discover potential issues.

Additionally, putting into place a methodical quality control process helps ensure that the end products satisfy industry standards. Finally, recording each step of the process enables better analysis and enhancement in future projects. By complying with these guidelines, manufacturers can improve the efficiency and success of their aluminum casting operations.

Resolving Typical Aluminum Casting Defects

Despite meticulous design and execution, aluminum casting projects can encounter various issues that may influence the finished casting. Common problems include porosity, which occurs due to trapped gases during the casting procedure, resulting in weak spots in the casting. To remedy this, it is essential to optimize the melting temperature and ensure proper venting in casting molds.

Another common problem is dimensional imprecision, frequently resulting from thermal shrinkage or misaligned mold configuration. Regular calibration of molds and precise temperature control can minimize these inconsistencies.

Surface defects such as roughness or inclusions may result from contamination or poor surface preparation. Implementing thorough cleaning and degreasing procedures is essential to obtaining a smooth finish.

Finally, poor filling may result in incomplete castings. Making certain of proper pouring speed and utilizing proper gating designs can help achieve better mold filling and total casting quality.

Latest Innovations in Aluminum Casting Processes

As industries continue to evolve, modern innovations in aluminum casting techniques are reshaping manufacturing processes. Advanced technologies such as 3D printing have emerged, facilitating the creation of complex geometries and reducing lead times substantially. This approach allows for rapid prototyping and customization, synchronizing production with specific client needs.

Furthermore, the integration of computational simulation tools enables precise mold design, boosting accuracy and minimizing material waste. Processes like vacuum die casting and squeeze casting are increasingly adopted, offering superior mechanical properties and surface finishes.

In addition, progress in alloy development are creating more lightweight yet robust aluminum materials, expanding their applicability across multiple sectors. Automation and robotics in the casting process streamline operations, improving efficiency and cutting labor costs. Combined, these innovations are setting new standards in aluminum casting, advancing product quality and sustainability while meeting the growing demands of modern industries.

Real-World Applications of Aluminum Cast Parts in Various Industries

The developments in aluminum casting techniques have considerably extended the range of applications across multiple industries. In the automotive sector, aluminum cast components are used for engine blocks, transmission housings, and wheels, facilitating vehicle lightweighting and improved fuel efficiency. Aerospace manufacturers favor aluminum castings for structural components due to their strength-to-weight ratio, increasing performance without undermining safety.

In the electronics industry, aluminum casings are frequently employed for devices, providing protection while effectively dissipating heat. Moreover, the construction sector uses aluminum cast parts in window frames, roofing, and architectural elements, taking advantage of their durability and resistance to corrosion.

In addition, the energy sector employs aluminum castings for turbine housings and other critical components, guaranteeing reliability in demanding environments. In general, the versatility of aluminum cast parts continues to drive innovation and efficiency across several industries, highlighting their integral role in modern manufacturing.

Frequently Asked Questions

Which Safety Measures Are Required During Aluminum Casting?

During aluminum casting, personnel should wear protective gear, ensure proper ventilation, handle molten metal carefully, keep a clean workspace, use safety equipment including gloves and goggles, and remain conscious of potential fire hazards.

What Methods Can Enhance the Surface Finish of Aluminum Castings?

To enhance the surface finish of aluminum castings, you can implement techniques such as improving mold design, using finer sand for casting, implementing appropriate cooling rates, and using post-casting treatments like sandblasting or polishing.

What Equipment Do You Need for Small-Scale Aluminum Casting?

Vital equipment for small-scale aluminum casting includes a furnace for melting, molds for structuring, a ladle for dispensing, safety gear for ensuring safety, and tools for final touches. These tools enable efficient and quality production in compact operations.

How Do Environmental Regulations Impact Aluminum Casting Operations?

Environmental regulations greatly shape aluminum casting operations by establishing controls on emissions, waste management, and resource usage. Compliance commonly calls for investment in more sustainable technologies, which can increase operational costs but ultimately promote sustainability and public health.

What Costs Are Involved in Establishing Aluminum Casting Facilities?

Setting up aluminum casting facilities generates multiple costs, including equipment acquisition, facility development, raw materials, labor, and compliance with environmental regulations. These expenditures can substantially impact upfront investment and ongoing operational budgets for producers.